|

||||

|

||||

|

||||

|

||||

|

Tag: Melba

Categories Business, Customisation, International, Manufacturing, New Products, Standards, Testing, Trench Cover

|

||||||||||

|

||||||||||

|

||||||||||

|

||||||||||

|

|||

|

|||

|

|||

|

|

||

|

||

|

The Thor Barrier |

|

|||||||||

|

Thor – Norse God and member of the Avengers is renowned for his incredible strength.

|

As strong as any Norse God. Reinforced with metal interior tubes and attached to two 28 kg feet, this has to be the strongest Barrier there is.

|

|

|

Thor is also renowned for summoning lightning bolts with the help of his mighty hammer, Mjolnir.

|

No need for a magic hammer, Melba Swintex has invested heavily in high-tech machinery so that we can offer LIGHTNING FAST production & lead times.

|

|

|

As mighty as Thor is, and he is mighty, he is even MIGHTIER when he works with his friends the Avengers.

|

Just like Thor, this barrier values his friends and it connects together using the high strength Thor Hook.

|

|

|

Thor brings the power of the storm.

|

When the storm hits, this barrier is not moving!

|

|

|

Find out more about the Thor Barrier by heading over to its very own Product Page where you can access all of the required information: |

|

|

The D-Hook & Utility Barrier

This new socialite on the scene has wowed the public with her style and grace, and now she comes with a few useful accessories such as the D-Hook. |

|

Perfectly Matched for Her Handbag. Or His Tool Bag. The Utility Barrier does not compare when it comes to strength, and with this strength comes great capabilities of customisation.

|

| You Can Leave Your Hat on. Or Hang it. The Utility Barrier is amazingly adaptable. It comes in 1m or 750mm wide with as many gates as you want, and at a height of 1m. With the ability for multiple D-Hooks, which can be used for extra ballast, hats, or to lie cables on whilst performing repairs. |

|

|

Even Fashion Models Have to Eat Darling.

But where to put your lunch box full of open faced smoked salmon sandwiches and crudites? Our D-Hook keeps those delicacies away from the dirty floor. |

| Accessorise, Accessorise, Accessorise.

This fantastic, robust clip can be positioned almost anywhere on the Utility Barrier Back Face, providing a variety of options and possibilities. |

|

|

Now For Something a Little European .

Dressed to impress in standard Red, this lovely colour is enhanced by the 250mm tall reflective material that sparkles in the headlights. This surely is something that will impress from Paris to Berlin. |

| In a Snazzy Yellow & Black Number.

The Utility Barrier can provide for every occasion, whether it be a slippery floor, a red carpet, or a problem with the lift in the lobby. The amazing attention to detail of the warning triangle means it can suit for all situations. |

|

|

Find out more about the Utility Barrier by heading over to its very own Product Page where you can access all of the required information. |

|

|

No Rising from the Ashes This Time

Relying on suppliers of the all metal Phoenix resulted in longer lead times, therefore we are moving away from the use of metal, and will focus on a completely plastic Litter Bin range.

|

| Manufacture Local

All of the Melba Swintex Litter Bin Range is now manufactured on site, and are available in a wide selection of colours. Company Branding can also be included on the each product.

|

|

|

There will soon be a new member to the Litter Bin Range, so keep an eye out for it! |

|

| In Case You Missed it… Here’s a run down of the year so far at Melba Swintex |

|

With fantastic new products, stunning lead times and standard items constantly replenished and kept in stock, it’s no wonder we are so busy. We therefore should look back on the year so far to see where the time has gone.

|

|

January

Precisely 12 months from the its launch in 2015, the Tuff Trench was supplied with a bonus feature – The New Anti-Slip Rubber Pads that can be securely fixed to the underside of the Tuff Trench to prevent movement under windy conditions. |

| February

During February, the New Tuff Foot was released onto the Traffic Management market. The stylistic design supplies a hefty 10kgs to each barrier, resulting in greater wind resistance on the Melba Swintex Barrier range. |

|

|

March

The Postman system made its way onto our customer’s doorsteps. The system has proved to be a great success due to increasing demand & demanding lead times on the market. The Postman takes the current temporary barrier system within utility works, and updates it by implementing a range of innovative features & increasing its strength and durability. |

| April

We caught a short flight over to Amsterdam for a week to showcase at the Intertraffic Exhibition. This event allowed us to network into areas we had previously never ventured, and opened up doors to new opportunities, and friendships. This also allowed us to speak to consumers one-to-one and get feedback on our services.

|

|

|

May

The Fantastic Four was born with the addition to the Barrier Foot family with the New Tuff-AT Foot. This great new foot satisfies both the needs of extra weight, and reducing the risk of a trip hazard when on site. The foot also has a little trick up its sleeve – the possibility to emboss with corporate branding, putting your name in the spotlight. |

| June

‘You’re my Wonderwall’ was the phrase that was stuck in the heads of everyone here in the office. The WonderWall™ Barrier was released once again due to increasing interest and demanding lead times. The product has been a huge success and continues to impress. |

|

|

|

|

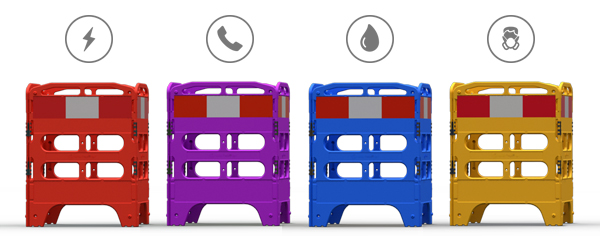

Introducing the new Utility Barrier from Melba Swintex. Completely manufactured within the UK, this barrier offers ultimate protection with incredible lead times, corporate branding, and a vast selection of colours to choose from.

|

|

|

|||||

|

|

|||||

|

|

|||||

|

Other Benefits and Features of the Utility Barrier include, but is not limited to:

Find out more about the Utility Barrier by heading over to its very own Product Page where you can access all of the required information. |

Melba Swintex has partnered up with the Business Growth Hub to make improvements within the business on entering new markets, improve our commitment to the environment, and to prioritise upcoming new products.

[pullquote align=”full” cite=”” link=”http://www.businessgrowthhub.com/case-studies/growth-service/melba-swintex” color=”” class=”quote” size=”16″]

The challenge:

The business was looking to break into international markets with a new export strategy as it was proving increasingly difficult to drive domestic sales. It also had a raft of new product ideas but the management team was unsure how to prioritise them and successfully take them to market. They also wanted to explore the feasibility of expanding their existing site, or possibly move to new local premises.[/pullquote]

Read the full Case Study published by Business Growth Hub Here.

Language

Language